In industries such as automotive, steel fabrication, and electronics, precise marking and welding answers are crucial. This overview addresses different marking equipment, from CO₂ lasers to dot peen markers, together with welding tools like fiber laser welders and handheld laser cleaners. In this article’s a guide to those technologies, their apps, and factors.

one. Laser Marking Machines

Laser marking presents substantial precision for marking metals, plastics, and even more. Common sorts consist of fiber, CO₂, and UV lasers, Every suited to precise materials and apps.

one.1 Fiber Laser Marking Machines (30W vs. 50W)

Fiber lasers are ideal for steel marking. The facility preference (30W or 50W) depends on substance thickness and marking depth.

30W Fiber Laser: Suitable for gentle etching and marking on metals.

50W Fiber Laser: Presents deeper and more rapidly engraving, perfect for industrial apps like automotive pieces.

one.2 CO₂ Laser Marking Devices

CO₂ lasers excel at marking non-metallic elements such as Wooden, leather, and specified plastics.

Traveling CO₂ Laser Marking Device: Created for continuous marking on conveyor traces, ideal for packaging and solution serialization.

Transportable CO₂ Laser Marker: Normally utilized for fast, on-the-go marking on leather-based, wood, or plastic goods.

one.three UV Laser Marking Devices

UV lasers, readily available in electricity solutions like 3W, 5W, and 10W, are useful for specific marking on plastics and fragile resources.

Apps: Ideal for circuit boards, health-related gadgets, and plastics exactly where small heat harm is required.

Cost Consideration: UV laser marking equipment is often far more expensive due to their precise apps and reduced energy options.

2. Dot Peen and Scribe Marking Devices

These machines make use of a pin or stylus to create a long-lasting mark, perfect for VIN quantities, gas cylinders, and metallic elements.

Dot Peen vs. Laser Marking: Dot peen is cost-productive for deep engraving on really hard surfaces, although laser marking is quicker and gives extra depth on metals and plastics.

Cylinder Marking Gadget: Important for marking gasoline cylinders with regulatory data or serial numbers.

3. Laser Welding Equipment

Laser welding offers sturdy, precise welds for metals like stainless-steel, aluminum, and wellable jewelry laser welding machine titanium, generally Utilized in automotive and aerospace industries.

three.1 Fiber Laser Welders

These machines use fiber optics to provide precise welds. Fiber laser welding is recognized for superior speed and negligible heat distortion.

Programs: Automotive elements, jewelry, healthcare machines.

Options: Ranges from handheld models to automated programs, with electricity options from 1000W to 2000W.

three.2 CO₂ RF Laser Welding for Non-Metals

Ideal for non-metallic products, such as selected plastics and fabrics.

4. Laser Cleansing Machines

Laser cleansing know-how, employing higher-electricity lasers (e.g., 500W, 1000W), efficiently eliminates rust, paint, and contaminants with no abrasives.

Laser Rust Removing: Gets rid of rust from metal and iron surfaces, preserving the fabric beneath.

Apps: Area preparing for welding, rust removing in automotive restoration.

five. Deciding upon Marking Solutions for the Market

Automotive Element Marking

Superior-run fiber lasers and dot peen markers are well known for VIN marking, section serialization, and branding.

Cylinder and Flange Marking

Gasoline cylinders and flanges typically call for dot peen or pneumatic marking devices that will develop deep, readable marks for regulatory compliance.

Jewellery and Precision Marking

UV lasers and small fiber lasers are suited to sensitive supplies, enabling specific marking with out injury.

six. Personalized and OEM/ODM Possibilities

A lot of corporations offer you personalized (OEM) and layout/production (ODM) products and services, allowing for enterprises to personalize machines for particular requires, including transportable marking machines or laser cleansing guns.

Advantages: Customization can improve tools for unique purposes, like specialized laser cleaners for jewellery or automotive part marking.

Summary

From marking to welding and cleaning, industrial laser and marking devices offer flexible methods for numerous programs. Deciding on the appropriate machine relies on components which include material kind, precision desires, wellable laser cleaning machine reviews and funds. Irrespective of whether You will need a CO₂ laser for marking leather or a robust fiber laser welder for industrial metalwork, comprehension Every single technologies’s strengths will help be certain efficiency and longevity with your functions.

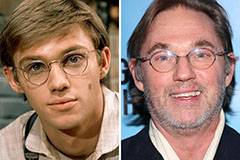

Edward Furlong Then & Now!

Edward Furlong Then & Now! Macaulay Culkin Then & Now!

Macaulay Culkin Then & Now! Nancy Kerrigan Then & Now!

Nancy Kerrigan Then & Now! Shannon Elizabeth Then & Now!

Shannon Elizabeth Then & Now! Richard Thomas Then & Now!

Richard Thomas Then & Now!